XMEK’s rotary seals are engineered to fulfill two essential roles: retaining vital lubricants within the system and preventing the ingress of contaminants like water and dirt. With the rise of specialty lubricants, we emphasize innovative seal design and meticulous material selection to navigate these evolving demands.

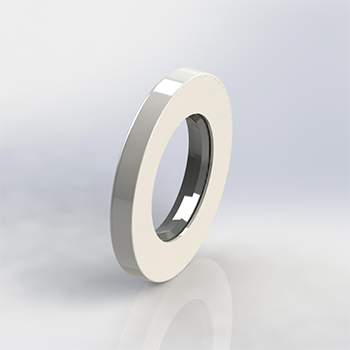

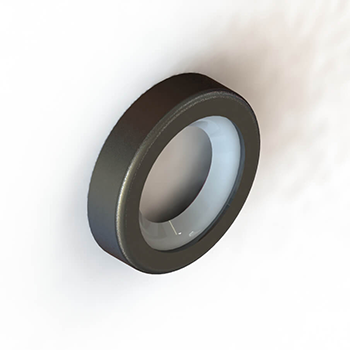

Shaft seals are used in rotary applications, such as a shaft or rotating bore.

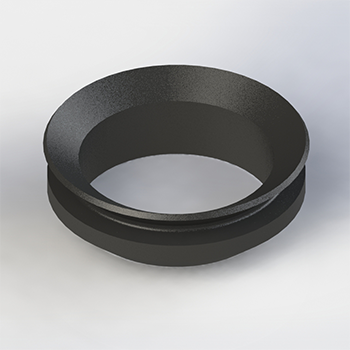

A v-ring seal is a one-piece seal which is mounted on a shaft and seals positioned axially against a counter-face and normally rotates with the shaft.

The construction of a v-ring seal is divided into three parts:

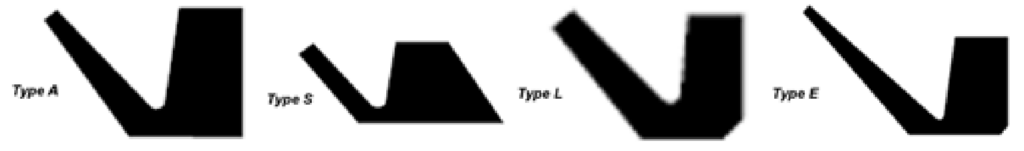

XMEK offers v-rings manufactured with four standard profiles.

V-ring type A with bevel back serves as a pressure less, axial rod seal with a very short mounting length, which is clamped on a shaft. The flexible sealing lip seals a counterface at a right angle to the shaft preventing dirt, dust and splash to enter the construction.

| Material: | NBR | FPM |

| Color: | black | brown |

| Hardness | 60° Shore A |

| T: | NBR: -30 till +100°C | FPM: -15 till +200°C |

| V: | ≤ 8m/s, from 8 to 12 m/s radial support is recommended. With speeds over 15 m/s the lip will come off the counter face. |

V-ring type S with bevel back serves as a pressureless, axial rod seal which is clamped on a shaft. The flexible sealing lip seals a counterface at a right angle to the shaft, preventing dirt, dust and splash to enter the construction.

| Material: | NBR |

| Color: | black |

| Hardness | 60° Shore A |

| T: | NBR: -40 till +100°C |

| V: | ≤ 8m/s, from 8 to 12 m/s radial support is recommended. With speeds over 15 m/s the lip will come off the counter face. |

V-ring type L with straight back serves as a pressureless axial rod seal with a very small mounting length, which is clamped on the shaft. The flexible sealing lip seals a counterface at a right angle to the shaft preventing dirt, dust and splash to enter the construction.

| Material: | NBR | FPM |

| Color: | black | brown |

| Hardness | 60° Shore A | 60° Shore A |

| T: | NBR: -40 till +100°C | FPM: -25 till +200°C |

| V: | ≤ 8m/s, from 8 to 12 m/s radial support is recommended. With speeds over 15 m/s the lip will come off the counter face. |

V-ring type E with straight back serves as a pressure-less axial rod seal with a very small mounting length, which is clamped on the shaft. The flexible sealing lip seals a counter face at a right angle to the shaft preventing dirt, dust and splash to enter the construction. The type E is designed for heavy use or is applied in situations where larger axial tolerances are required. This profile is delivered for shafts from Ø450 to Ø2010 mm.

| Material: | NBR | FPM |

| Color: | black | brown |

| Hardness | 60° Shore A | 60° Shore A |

| T: | NBR: -40 till +100°C | FPM: -25 till +200°C |

| V: | ≤ 8m/s, from 8 to 12 m/s radial support is recommended. With speeds over 15 m/s the lip will come off the counter face. |

XMEK lip seals are specially designed to resist higher pressures than a classic oil seals and can be used with shaft velocities of up to 40 m/s.

Advantages:

Searching for detailed insights, have a technical question, or want to learn more about our logistics / stocking services? Our team at XMEK is always ready to help. As industry-leading experts in application engineering, material selection, and world-class distribution and supply chains, we're committed to providing you with unparalleled quality and efficiency.

Corporate HQ

"*" indicates required fields